STG-M252S

The second generation of Steiger computerized flat knitting machine is efficient and stable. The machine has the function of bidirectional narrowing, enforced knocking over, bilateral stitch, automatic plus-minus of needle, multi needle gauge, and the successive knitting of front and back weaving products, which are pioneering and unique in the industry. The max speed reaches to 1.7m/s, renovating the efficiency of new computerized flat knitting machine.

The machine adopts CPU dual-core processor. Optimize the system and make the operation of knitting become easier, timesaving, as well as display the potential of updating hardware at maximum. The system memory can be extended unlimitedly, and can input plenty of patterns and according to the requirement of producing to invoke. Optimize the program system then only need one layer picture to display the intarsia, jacquard and partial jacquard. For the full needle shape, it has the exclusive narrowing sign, which is the same operation with single pattern, without needing to make small picture. All these contribute to optimize the processing for pattern-making personnel and enhance the production efficiency.

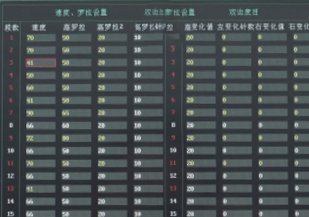

| Specifications | |

|---|---|

| Gauge | 3G, 5G, 7G, 8G, 9G, 10G, 12G, 14G, 16G, 5/7G, 7-14G |

| Needles/Knittig width | 728N/52Inches |

| Knitting system | Single carriage with double systems |

| Machine system | Steiger system |

| Knitting speed | Max speed 1.7m/s;24 section programmable speed |

| Stitch density | 36 segments of electronic control,the use of subdivision technology,adjustable range:0-650,more accurate control of the length of fabric |

| Racking | Motor driven;max 2 inches |

| Transfer | Both front and back,not affecting by the carriage direction,sepepately knitting |

| Sinker system | The stepping motor can adjust the active sinker and can be adjusted according to different fabrics to achieve a variety of collecting and putting effects. |

| Needle actuator | 8 section of electronic needle selector |

| Comb device | Comb device complement with scissors/lips device, and this device adopts releasing principle, in order to effectively realize yarn hanging and sloughing function |

| Roller device | Main roller,comb device,128 section automic control, subdivision adjustmen |

| Conveyor yarn device | Roller feeding device ensures timely yarn delivery |

| Double yarn knot antenna | The maximum yarn knot stops, and the small yarn knot runs at the lowest speed for 4 lines. |

| Blowing device | The left side scissors machine and the falling cropping increase the blowing function, effectively reducing the false alarm stop phenomenon caused by the yarn. |

| Color changing device | The 2*8 yarn feeder group is arranged on the left and right sides of the 4 double-sided guide rails. After modifying the yarn feeder stopping point, the system reprograms the pattern and checks the yarn feeder condition. In order to prevent the yarn feeder from being stopped incorrectly,which might cause the products to fall and the yarn feeders to overlap, |

| Protection device | Automatic stopping,device if yarn broken,yarn knot,batching,striking,completion,overload,designated starting and stopping,program error happen. |

| Driving system | Belt drive,AC servo motor control |

| Safety device | The protective cover is equipped with a stopping sensor,emergency stopping device,power off device, and the whole machine cover to reduce noise and dust. |

| Date imput | Through the U disk,computer connection for direct input of data. |

| Fueling device | The fuel tank at the base of the needle bed refuels the carriage when the carriage is passing. |

| Size and weight | L*W*H:2970x940x2010 mm; Net weight: 1145 kg |

| Power supply system | Voltage: AC 220V/380V;Frequency: 50HZ/60HZ;Power:2.0KW |

Display Details

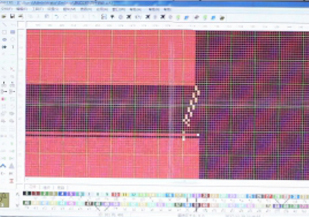

Bidirectional narrowing

In allusion to the transfer and some difficult fabric, this function can reduce the knitted lines. The racking is able to work simultaneously and can achieve bidirectional narrowing when the carriage operating. Just one rotation can achieve transfer, compared with a normal model that requires two revolutions to complete the needle-transferring movement, the efficiency is increased by more than 90%.

Enforced knocking over

When woven products,scissors and clamps work with each other,so it can cut the yarn which connect with fabric but temporarily unused. This can avoid the waste yarn and product damage or because of thread is too long,possible existence of yarn winding and so hazards. Wasted time of hand-cut yarn will be save and increase efficiency,and easier to production management.

Bilateral stitch

The bilateral stitch of fabric can be adjusted to control the length, only need to change some values. It does improve the stability and consistency of production.

Successive knitting

The front and back garment pieces of the fabric are continuously woven, and the number of single or woven fabrics can be set separately to continuously produce the required pieces.

Four Yarn Feeders

When an emergency or simple maintenance work (such as threading, needle changing, cleaning, etc.), you do not need to turn off the main power supply. Instead, press this switch to lock the machine and stop working, which can effectively avoid accidents and emergencies. When it occurs, it can more effectively protect humans and machines.

Intelligent Program

Only need one layer picture to display the intarsia, jacquard and partial jacquard. Any one picture can complete the program. No need two-layer or three-layer pictures.